How can we help you?

I want to join e-commerce!

I want to boost my sales!

My current website does not have any sales & visitor!

I need proffesional digital marketing advise!

I want to join ecommerce

Want to allow your businesses to reach a wider market ? eCommerce website is here to help !

You could get a professional eCommerce website with our self-developed NEWPAGES merchant system which possesses various and complete eCommerce function at lower cost. Start selling your products and services online !

I want to boost my sales

Facing difficulties from finding new sales ? Don't worries! We are expert in digital marketing.

can bring a lot new visitor to you from our SEO strategy, increase and secure your sales by Facebook Remarketing, you can even get more visitors from our NEWPAGES Network Platform.

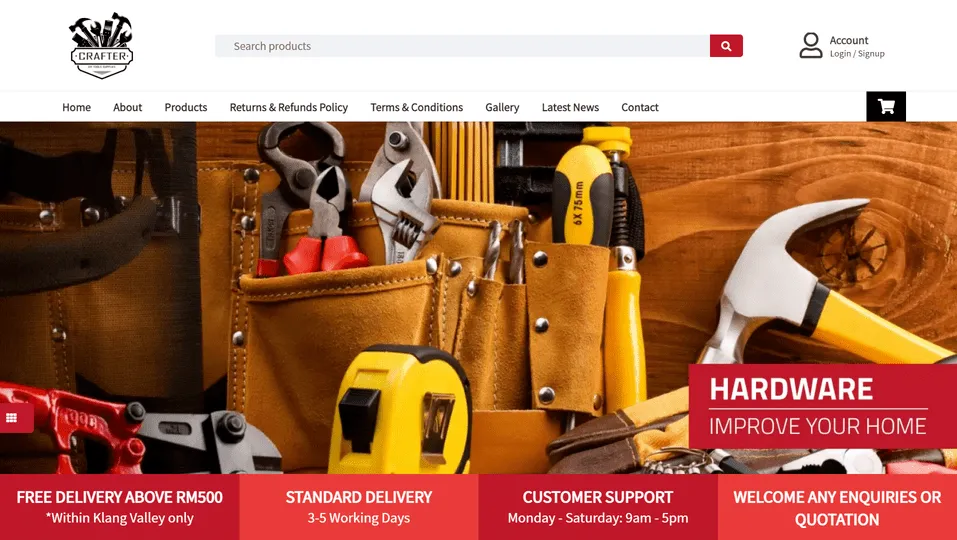

My current website does not have any sales & visitor

You are agreed to create your cooperate website for only RM399 per year ? But your customer doesn't not !! They cannot find you on Google or any others search engine.

Please don't expect this website can bring any sales & visitor for your company. See how we use Professional Digital marketing ways to help our customer maximize their exposure & sales.

I need a professional digital marketing advise

PPC or SEO ? CPC? TA? SEM? CTR? Google Ads? Facebook Ads? Facebooking Remarketing ? Boost? Pixel? Pretty sure you are still confusing about term, but they are very useful strategy for different situation and scenario.

Dont know how to make use of them ? Contact us now to know how to use them at the lowest cost !

How can we help you?

I want to join e-commerce!

I want to boost my sales!

My current website does not have any sales & visitor!

I need proffesional digital marketing advise!

I want to join ecommerce

Want to allow your businesses to reach a wider market ? eCommerce website is here to help !

You could get a professional eCommerce website with our self-developed NEWPAGES merchant system which possesses various and complete eCommerce function at lower cost. Start selling your products and services online !

I want to boost my sales

Facing difficulties from finding new sales ? Don't worries! We are expert in digital marketing.

can bring a lot new visitor to you from our SEO strategy, increase and secure your sales by Facebook Remarketing, you can even get more visitors from our NEWPAGES Network Platform.

My current website does not have any sales & visitor

You are agreed to create your cooperate website for only RM399 per year ? But your customer doesn't not !! They cannot find you on Google or any others search engine.

Please don't expect this website can bring any sales & visitor for your company. See how we use Professional Digital marketing ways to help our customer maximize their exposure & sales.

I need a professional digital marketing advise

PPC or SEO ? CPC? TA? SEM? CTR? Google Ads? Facebook Ads? Facebooking Remarketing ? Boost? Pixel? Pretty sure you are still confusing about term, but they are very useful strategy for different situation and scenario.

Dont know how to make use of them ? Contact us now to know how to use them at the lowest cost !

services provided in ONESYNC Platinum

What is ONESYNC

ONESYNC is a SaaS product offered by NEWPAGES Network, it is a self-developed software by NEWPAGES R&D Team without using any 3rd Party open source like WordPress, Magnento and etc.

Any ONESYNC website is coming together with our NEWPAGES MERCHANT SYSTEM also known as NMS. Our customer can manage their website at laptop/mobile devices with NMS. We strongly believe ONESYNC will become an very important tool which will greatly improve the efficiency and lower the cost for digital marketing.

Why Choose ONESYNC Platinum

All in 1 Marketing Strategy

The essence of marketing strategy, Inbound Marketing, Intercept Marketing, Engagement Marketing, Affiliate Marketing. You can simply get all of them in just by ONESYNC website.

Attract target audience and potential customer by creating and publishing content such as products, offer, news, services that provide values. We will optimize the content with an SEO Strategy.

You had bring potential customer to your company website. With our intercept marketing, visitor can direct proceed to close the sales directly before your competitors have been joining the tables.

Create meaningful interactions with your buyer and customer with Promotions, Newsletter, personalized content, feedback and etc to ensure your customer always royalty to your brands and products.

Have you ever think before ? Your customer can help you to promote your products and services. With affiliate marketing, your buyers and customer can earns a commission&benefits for themselves, while you can easily get more new sales.

More Organic Traffic

Your physical store isnt operating at all but you could get business opportunity anytime with our TDO and right SEO implementation.

Get ahead of your competitor

SEO could be very expensive and requires highly-skilled professionals to get your website to the first page. But you can get it easily with our ONESYNC Platinum website at lower cost. Which makes it harder for your competitors to compete with you.

Analytics and Statistic

Our reporting and statistics dashboard is available 24/7 and access to view the website performance will be given. On top of this, we will send a monthly SEO & website performance reports to every of our customers.

Make your work

easier than ever

We understand the pain of using a complicated system. It is not efficient and will cost more than what you expected to perform. So, We are here to help.

Market place synchronization

More channels, more sales. Get started to sell your products to all popular marketplace in just few step, and manage them easily in just 1 place!

NEWPAGES merchant system (NMS)

Our merchant system is a tools to help you create your successful online store. With our system, you can see your new signup member, receive & update your order status, you can even create your own promotion campaigns! Besides, we have various of tool like delivery remind, low stock alert to ensure you have a smooth online sales flow.

E-commerce

Get the ecommerce website that sells more. Running an online business is not easy! Stop struggling and spent more money to get those "features". We understand your pain points and we really do. So we have those ready for you without additional cost. That's why our ecommerce website comes with an end-to-end solutions.

Promotion campaigns

Store voucher

Wholesales price

Product variant

Invoice system

Special request

Search engine optimization (SEO)

Better ranking, better revenue. We helped numerous of Malaysia SMEs with SEO to help them to get their website onto the first page of Google’s results.

Trust from

all of customers.

Over the years, we have served large corporations, SMEs, non-profit organization. We have our own web designer team to give your business a visual stunning and engaging website that will convert visitors into buyers.

websites done

since 2007

More websites

in future

Start your

journey to

Excellence now

Communication

Bring the idea to life! Communicate with our professional sales to discover how we can help in your business

Domain Register

After strategizing idea, get your website a domain name. (We are MYNIC authorized domain reseller, which ensure you fully own the domain)

Content Collection

Provide your company information and product to our team. (Our production team will always assist you! )

Website Development

Design, Digital Marketing & Strategies, SEO and all setting will be execute, debug.

Ka poom!

a tailored made

company website

is prepared.